In the early 1970s, the U.S. Forest Service developed a computer program that mathematically calculated the highest volume of lumber that could be sawn from a log of specified dimensions based on what it called the “best opening face.” Soon, computerized sawing equipment incorporated this computer algorithm into their equipment along with scanning technology that allowed the log to be spun and scanned prior to sawing, thereby allowing the computer to determine just exactly where that first critical cut should be made. The resulting “face” of the log then, would produce the widest pieces of lumber, and subsequent narrower lumber would be produced as the log is turned. In this photograph, the sawyer, or the computer he operated, determined that the best first cut would be on what is the top of the log in the picture.

In reality only the larger pieces closer to the core are what you want the sawmill to cut. The smaller pieces can be cut by most a table saw from milled wood much cheaper. Also, the smaller pieces close to the bark are cut out of the “slab” wood which is not cost effective with portable sawmills.

Cutting through the bark (and the dirt, gravel, etc that is in the bark) is the hardest on the saw blades, you want to cut to the cant with a few cuts as possible. Sawmill blades are between $25 and $150 each, so you want to maximize their life spans. Figure your slab cuts first, then layout the cant for the lumber you want.

Notice in the top image, the larger lumber is cut closer to the core. This is because the heartwood is the strongest. You should plan your cut list accordingly.

Planning your lengths

The longest log that we can cut is 16ft. This is fine if you want 8ft or 16 ft lumber, but if you want a significant amount of 10, 12, or 14 ft lumber, you should cut your logs to length accordingly. It wastes time, wood and blades to cut 16ft logs if you want 12 ft lumber.

Quality Logs

Our sawmill will cut up to 32 inch diameter logs that are under 16 ft and under. In planning your logs and lumber take this into account. We can process larger logs, but there are other considerations involved in larger logs. We are happy to discuss this with you.

When cutting the logs for milling (and planning your cuts) pay attention to the quality of the log. Some logs have rot in places or have been shattered when it fell. Milling around rot is not an issue, it just limits the optimal cuts for a log. If the tree broke when it fell, you are going to want to manage and cut your log lengths well away from any breaks.

Further considerations

Not long after the computerized saws were capable of producing the highest amount of lumber, or “yield” from a log, technologists figured out how to allow the mill operators to assign market values to the different sizes of lumber in “value tables” built into the software. This allowed the mill operator to then produce not the highest “yield” of lumber in board feet (one board foot is equal to a square piece of wood 12 inches long, by 12 inches wide, by 1-inch thick), but the highest value of lumber in dollars based on ever-changing current lumber market values.

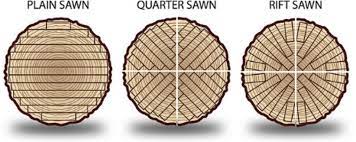

This system works well for softwood lumber, such as pine, fir, and spruce. For these most of the value is determined by the dimension of each piece. But in hardwood lumber production, the real value of the lumber is determined by the internal characteristics of the log…the number and size of knots and other defects, the coloring and figuring of the wood, and the surface area of “clear units” in each piece of lumber. These characteristics are determined again by the sawing technique used for each log. The three most common methods of sawing hardwood logs are called

- plain or flat sawn – the most common and highest yielding method.

- quarter-sawn – the most popular for certain applications where high grained wood is desired such as furniture.

- rift sawn – used when straight-grained lumber is desired.

What are you going to use your new lumber for?

There are a number of legal consideration in using custom sawn wood.

The stamp is required for Structural wood, but much of the wood used in construction is not structural wood such as decking, flooring, trim, siding, etc. Further the unstamped wood can be used in non residential buildings.

One more thing to consider

Portable Sawmills can process logs up to 60 inches in diameter. The problems with these much larger sawmills are:

- Machine cost – The more expensive the machine the more expensive the hourly rental

- Blade Cost – the blade for a 60in sawmill costs between $110 and $185. The cost of a 32 in sawmill sawmill blade is between $25 and $50.

- Log handling – a 20ft long 32 inch hardwood log can weigh around 3,500 lbs. The same length log at 60 inches is about 12,280 lbs.

Milling your own logs can be very cost effective, but there some ways to make it more cost effective. Keep the sawmill as small as possible to keep the rental rates down. A saw mill blade will only cut so many board feet regardless of size of sawmill. Also, remember it only takes one nail to ruin a blade.